Aug 23, 2021

Raising the Roof: Another LNG Canada Milestone is Achieved in Kitimat

Share

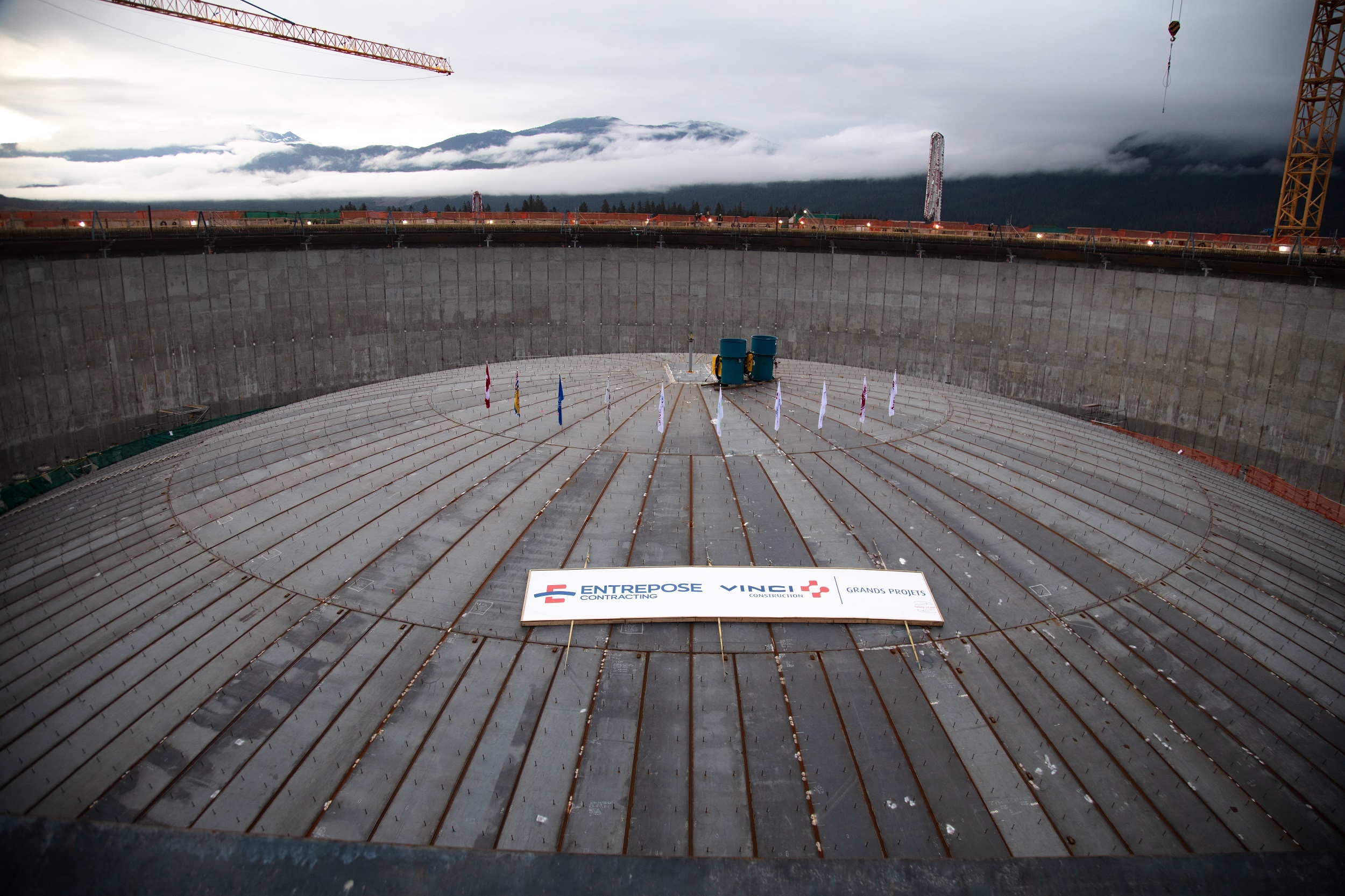

In what has already been a year of key engineering and construction milestones at the LNG Canada export facility in Kitimat, this could be the capper (so far): An enormous circular roof made of steel and weighing 1,540 tonnes was carefully raised into position earlier this month, and now sits securely atop the site’s LNG storage tank, making a dramatic new addition to the landscape.

The distance from the tank’s reinforced concrete floor to the top of its domed ceiling is 56 metres, or about 180 feet, making the entire structure taller than Rogers Place arena in Edmonton, and just six meters shorter than B.C. Place stadium in Vancouver. Such comparisons are apt, because from a distance, the LNG tank could almost be mistaken for a modern sports arena.

One of the world’s largest LNG tanks with 225,000 cubic meters of usable interior space, it will store liquified natural gas produced at the LNG Canada facility. The LNG will be piped from the tank into special ocean carriers for export to countries that require low-carbon energy.

Planning and building such a large piece of infrastructure is no easy feat, says Naman Maheshwari, the LNG tank project lead. “This is a very complex project, with multiple work scopes and contractors,” he notes. Raising the roof required enormous precision, attention to safety and technical capability.

So how does one raise a roof equivalent in weight to eight Boeing 747s? Slowly, says Maheshwari.

The roof was lifted from ground level using light air pressure from fans, at just 22 millibars, or about .32 pounds per square inch (psi). This is a very low pressure, less than one-one hundredth of a regular car tire, but sufficient because the roof covers a lot of area: its diameter is 92 metres.

The lift took almost three hours, starting early in the morning after “final-final checks,” says Maheshwari. A group of inspectors went inside the tank while it pressurized. The roof was initially raised just a couple of meters to ensure pressure seals inside the tank were working properly, and that the roof was elevating in a balanced position. With all systems working flawlessly, the main operation commenced. Once the roof was fully raised, more than two dozen welders secured it to its final position. Later that day, the air pressure inside the tank was released.

For everyone involved, the lift was extremely satisfying. But it represents only part of the tank work required. “The tank is now roughly 40% finished,” says Maheshwari. “The critical path now moves from civil works to mechanical, and provides the opportunity to open more work fronts inside the tank.” Eventually, the roof will be encased in concrete, matching the tanks walls, and an inner tank made of 9% nickel alloy steel will be installed.

“The successful LNG tank roof raise represents another accomplishment for the LNG Canada project, and demonstrates once again the high degree of professionalism, skill and care that go into our facility,” says LNG Canada CEO Peter Zebedee. “In June, we saw the arrival of our first main cryogenic heat exchanger and pre-cooler units, and we’ll start receiving the first of our modules this fall. We’re making great progress, and we’re doing it safely. It’s an exciting time for the LNG Canada project as we continue to go vertical. I’m tremendously proud of the entire project team.”